DESCRIPTION

DECOFLEX MS-40 is one-component sealant and glue on the basis of a hybrid MS polymer for sealing and gluing most construction, metal and plastic materials. It is used for sealing and gluing all types of construction materials – also suitable for gluing construction under vibration, for sealing joints gaps vacuum systems, for aluminium structures, containers, cisterns, silos. It has excellent mechanical properties, is resistant to various weather conditions and UV and can be painted over.

CHARACTERISTICS

- Excellent adhesion on most construction materials – concrete, brick, wood, aluminum, iron, stainless steel, copper and various plastics

- Good output even at low temperatures

- Does not slump in vertical joints

- Excellent characteristics, great hardness

- Environment friendly: contains no solvents, isocianate and silicones

- Totally chemically neutral and odourless

- Can be painted over with most paints and varnishes on the basis of epoxy, polyurethane and water

- Shrinkage lower than 1%

- Resistant to various atmospheric conditions and aging, also UV resistant

- Chemical resistance good to: water, aliphatic solvents, mineral oils, fat, low concentration anorganic acids and bases

- Colour: grey, white, black, brown, colourless

PACKAGING & STORAGE

Packaging units:

Cartridge: 290 ml; Sausage: 600 ml

Storage:

In a dry and cool storage place at temperatures between + 5°C and + 25°C and in the original/sealed package.

APPLICATION

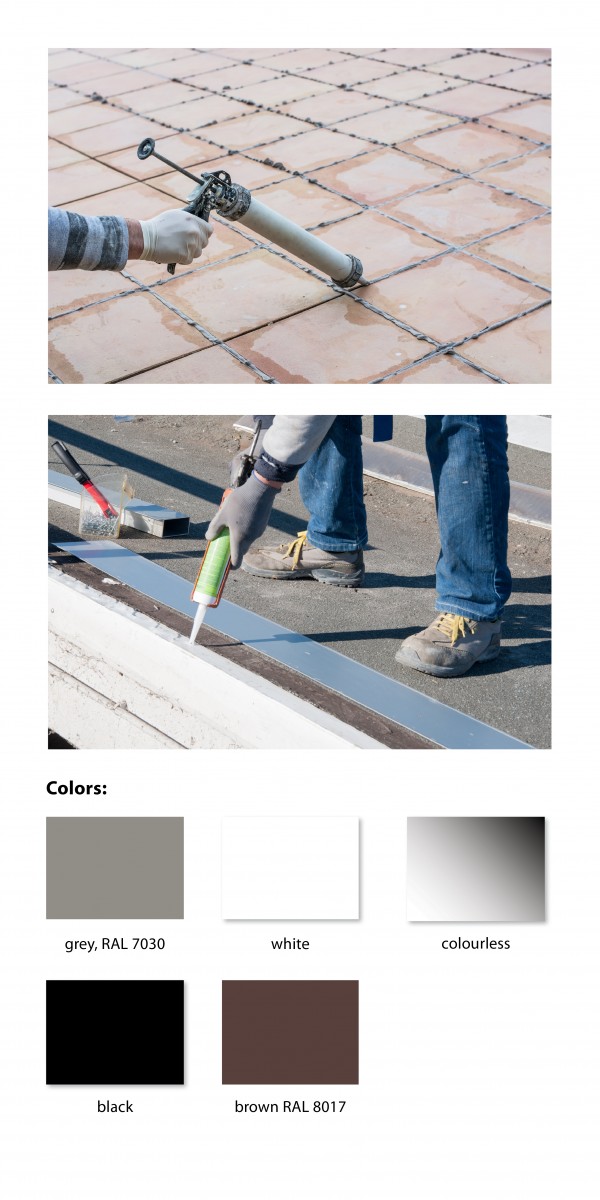

Surface preparation:

The surface of the joint must be hard, clean, dust and fat free. Remove all separated and badly attached pieces.

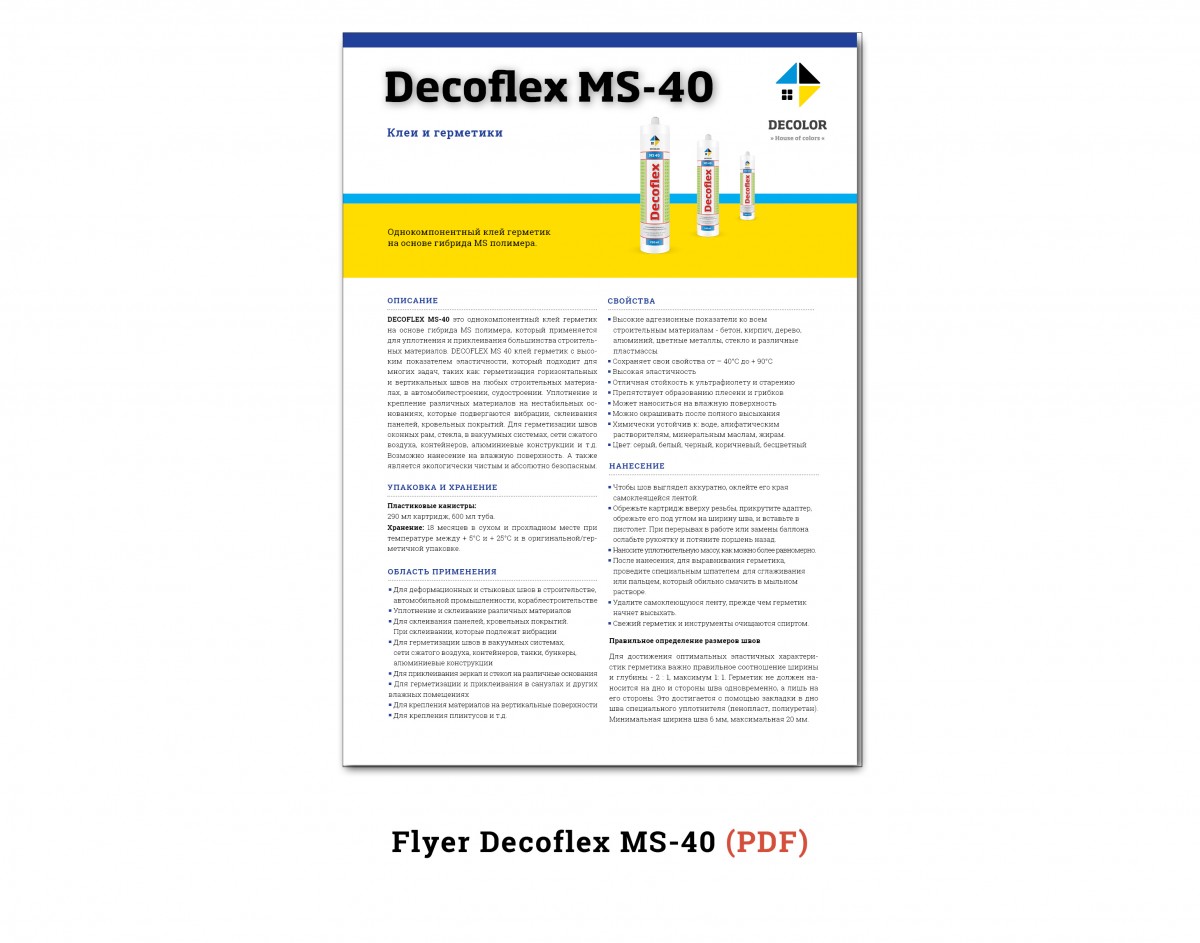

The surface of the joint must be hard, clean, dust and fat free. Remove all separated and poorly attached pieces. If you want joints to look nice tape the edges with masking tape. Cut the cartridge at the top and screw on the nozzle which has to be cut accordingly to the width of the joint and placed in the gun. During work interruption release the handle on the gun and pull the piston back. • The sealant should be applied as evenly as possible. At the end, level the sealant with an appropriate instrument or a well soaped finger. Remove the masking tape before the sealant starts to harden.. The sealant must not grip the bottom of the joint, but only its sides. We can achieve this with the use of underlying materials, onto which the sealant has no adhesion (foamed polyethylene, polyurethane). The minimum joint width is 6 mm, the maximum is 20 mm. Fresh sealant and tools can be cleaned with alcohol.

Correct dimensioning of dilatating joints:

For the optimal elastic characteristics of the sealant, a correct width/depth ratio is important (2:1) or a maximum of 1:1. The sealant must not grip the bottom of the joint, but only its sides. We can achieve this with the use of underlying materials, onto which the sealant has no adhesion (foamed polyethylene, polyurethane). The minimum joint width is 6 mm, the maximum 20 mm.polyurethane). The minimum joint width is 6 mm, the maximum is 20 mm. Fresh sealant and tools can be cleaned with alcohol.